Bon Accord Hammer Users Guide

The range of Bon Accord Hammers were designed in the 1930s and apart from minor changes have remained the same since. The main improvement in the intervening period has been to Air Compressors, which now operate at consistently higher pressure. We would advise that all Air to your Bon Accord Hammer be regulated to 3.5 to 4.5 bar.

Operating Air Pressure 3.5 to 4.5 bar. ( 60 psi)

Higher Pressure will result in increased vibration

Ensure all chisels are in good condition

Keep hands and arms warm to minimise effects of vibration

Pneumatic hammers release vibration into the work and consequently into the hands and arms of the operator. The operator should take every precaution to minimise the effect of this vibration and report any injury to the supervisor.

Vibration levels from properly operated Bon Accord Hammers are as follows.: From 10 to 18 M/S2 Depending on model.

Recommended Air Pressure for all sizes

60-80lb. per sq. inch

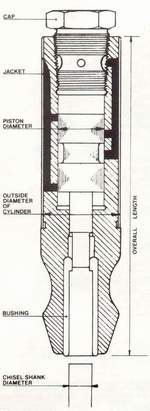

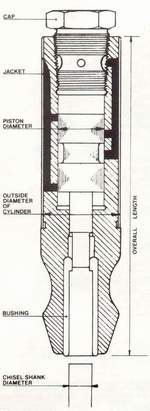

CONSTRUCTION AND MAINTENANCE

The section shows that in the construction of the tools there is a minimum number of parts, the piston being the only moving part. All components are made of special steel, heat treated and ground to minimise wear. Light weight and minimum vibration combines to make a perfectly balanced tool, which can be easily held and manipulated without fatigue.

The only attention necessary to ensure troublefree running over a long period is attention to cleanliness and regular lubrication through the nipple.*

When repairs do become necessary we recommend that tools should be returned to our works so that correct parts can be fitted to ensure utmost efficiency.

If ordering spare parts give size and serial number as stamped on the hammer for which they are required.

*We recommend the use of 3 in 1 oil, which lubricates effectively without clogging or gumming.

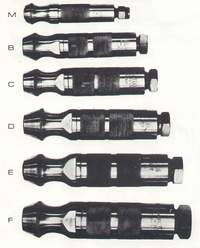

THE COMPLETE RANGE OF BONACCORD PNEUMATIC HAMMERS

RECOMMENDED SIZES AND APPLICATIONS

The six sizes of `BonAccord' Pneumatic Stone Hammers peaning, bushing and masoning. In general the smaller tools illustrated above and listed on the opposite page, provide for each class of work are used for marble,stone and other the most comprehensive range available to stoneworkers and soft materials, while the larger tools are preferred for granite ensure that the requirements of the most exacting craftsman and hard materials.am catered for. Size Midget Is very suitable for f i ne sculptural work and drilling for leaded letters. Sizes B and C In addition to the stoneworking purposes for which they are are suitable for delicate to medium lettering, tracing, carving, designed. these valveless pneumatic hammers are adaptable finishing and drilling of leaded letters. SizesD and E are for for other work such as light rivetting paint scraping, brick heavy carving, lettering, bush tooling and masoning. Sizes F cleaning. boiler scaling, concrete bushing and drilling, etc., if and G will handle the heaviest class of work such as roughing, provided with suitable chisels or bits.

REPAIRS EXECUTED TO ALL MAKES OF PNEUMATIC HAMMERS

The "BonAccord" Pneumatic Stone Hammers are made in a range of sizes to handle work from delicate tracing and carving to heavy roughing out and bushing on Granite, Marble, Stone, Concrete, and Cast Stone. Slate, etc. They have been developed and improved during the years they have been on the market and are undoubtedly the best hammers now available to stoneworkers. They are economical to operate and maintain, and the use of specially selected materials and precision workmanship ensure their durability.

GUARANTEE

We guarantee all hammers free-from imperfections in material and workmanship. , and any broken or defective parts will be replaced if returned to our works within one year from date of purchase. This does not apply to repairs or replacements due to abuse or neglect.